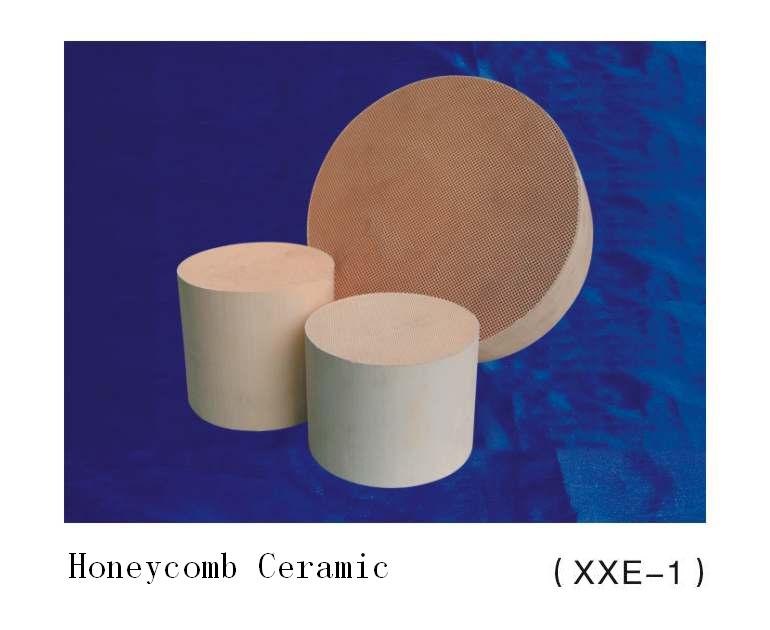

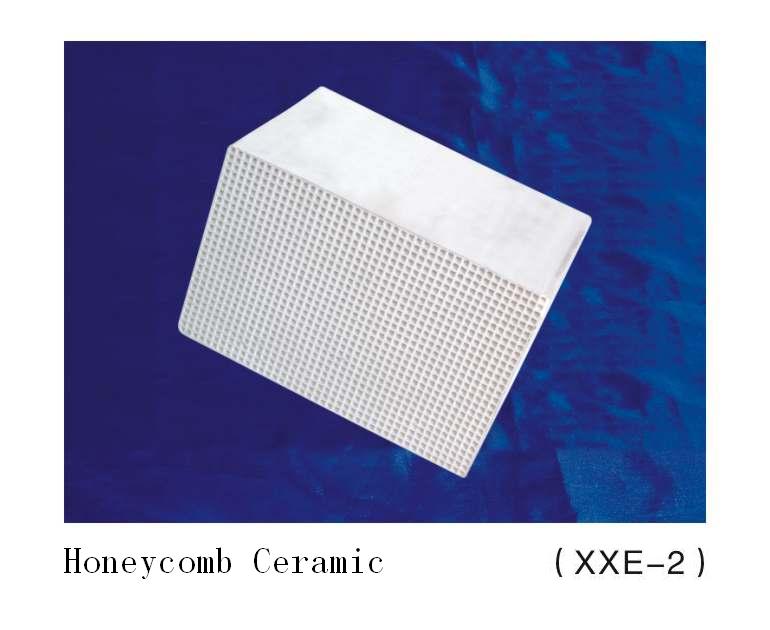

Honeycomb ceramics

Honeycomb ceramics has high surface area, low air flow resistance, widely application range as follows0

Catalyst agent-reducing organic oxidation temperature; purifying industrial exhausting air

heat transfer agent- saving 12% energy in heat exchange

refractory stove: quality/small volume ratio, fast heat transfer and high heat effect

gas burning distributing plate: complete burning, energy saving is 10%

Physical property

|

size |

D×H |

surface area |

void volume |

liquid burthen |

Pressure drop |

Max F factor |

Hydraulic diameter |

hardness |

|

mm |

mm |

m2/g |

% |

m3/m3 |

Mpa/m |

mm/s(ks/m) |

mm |

Mohs |

|

Φ6-150 |

6-150 |

1200-605 |

61-97 |

0.5-15 |

1-5 |

3-1.6 |

4.7-9.7 |

6.5 |

|

150-50 |

Chemical composition

|

chemical composition |

content |

chemical composition |

content |

|

Al2O3 |

20-85 |

anti-acid |

099.8% |

|

SiO2+Al2O3 |

92 |

anti-alkali |

086% |

|

Fe2O3 |

<0.8 |

refractoriness |

012000 |

|

Out porous ratio |

7.0-10% |

thermal stability |

no crackle after three times |

Technical parameter

Dimension -6-150 producing different size according to customer0s demands in this scope.

Quadrate pore: density 150-400pore/inch

the ply of the board between pore 00.3mm

Compressive strength .vertical0 12Mpa radial0 4Mpa

Coefficient of heated expanding 1-2×10-6/0

Max operation temperature:-within 15000

Resistance to thermal shocks: 9000

Strong acid and alkali resistance

|